The test benches are designed to perform maintenance tests according to the CMM of non rotating aircraft hydraulic components such as actuators, valves, fuses and servo assemblies. These systems are fully computerised to provide maximum control efficiency, leading to repeatability of test procedures and accurate test results. The test stand is suitable for all 5000 psi A/C system components like installed on A380, A350 and B787.

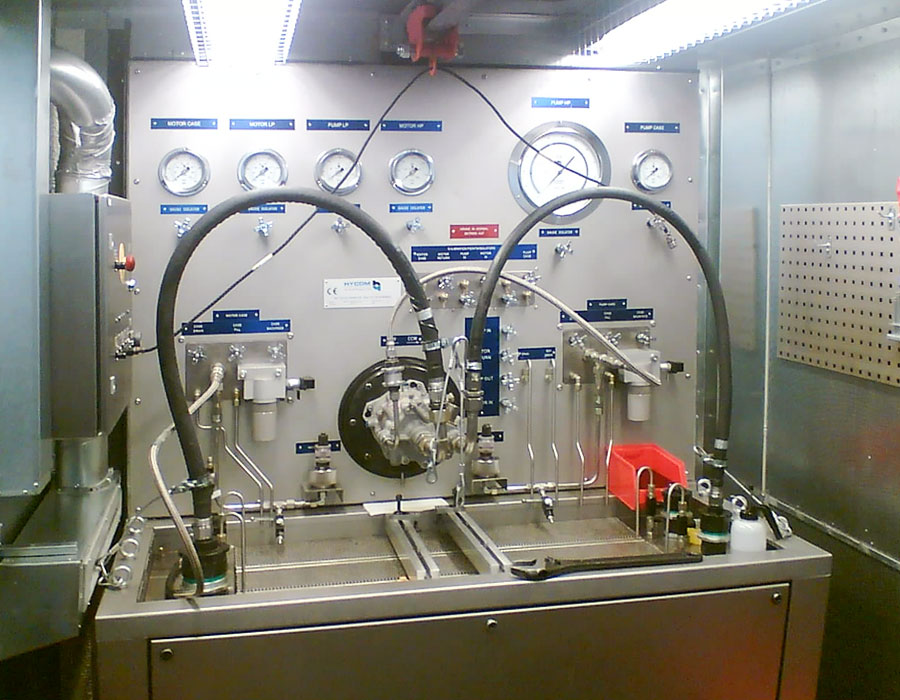

• Power pack with accessories

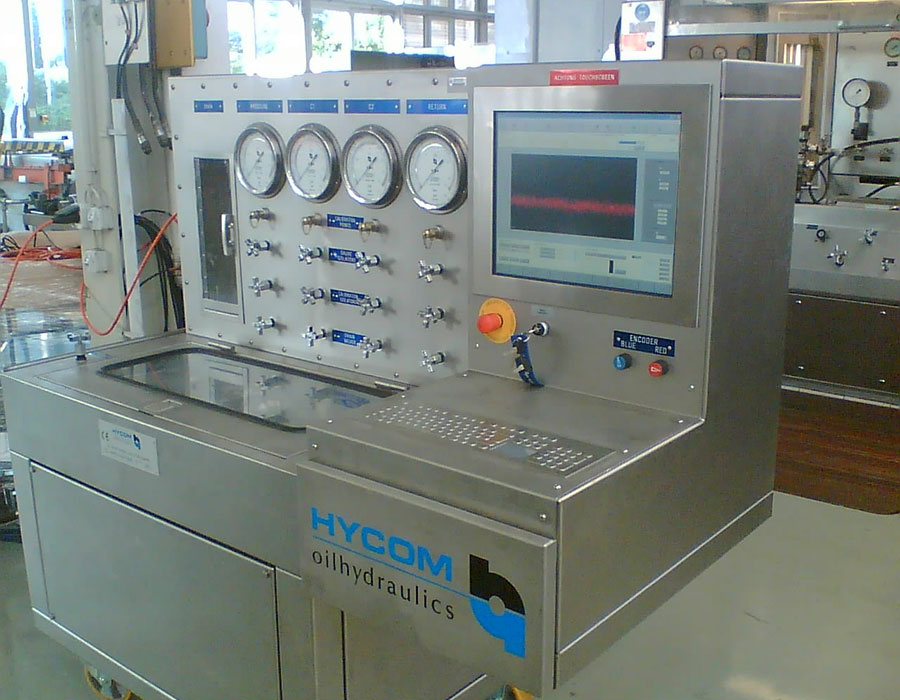

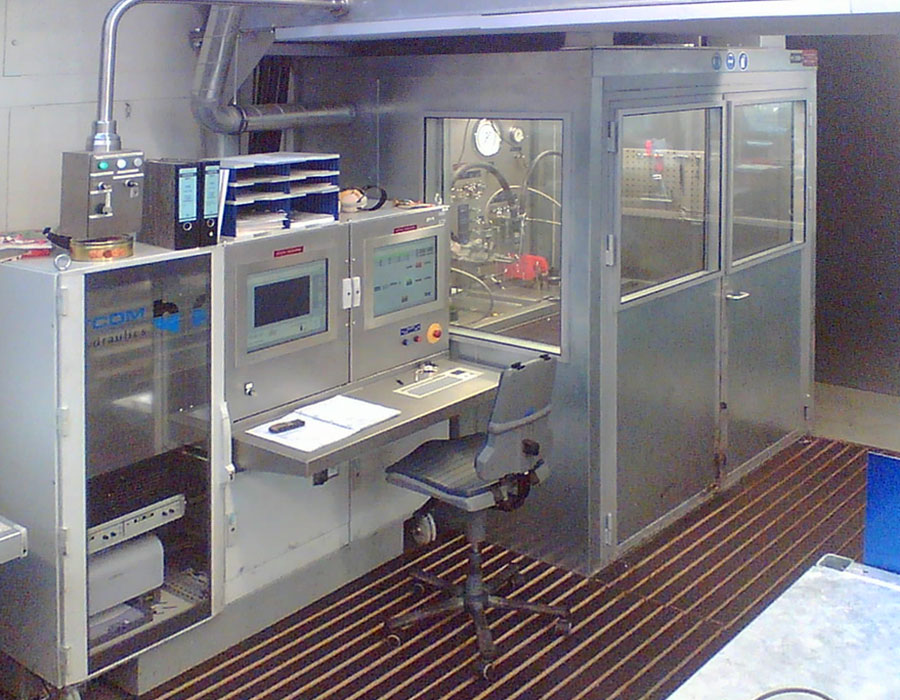

• Test station cubicle

• Electrical cabinet

• Computer control console

Supply pressure circuit characteristics:

– 0.5-350 bar / 8-5000 psi (up to 240 ltr/min)

– 2 pcs hydraulic main pumps

– Proportional adjustable flow control

Maximum static proof pressure circuit:

700 bar / 10150 psi (up to 5 ltr/min)

Return pressure circuit characteristics:

0-20.7 bar / 0-300 psi (up to 270 ltr/min)

Multifunctional system ports:

– 4 ports, all of them can be either pressure, return or closed

– Automatic switch of ports without disconnecting UUT

Flow measurement system:

– 1 pc in each pressure line (high flow 1-150 ltr/min),

– 1 pc freely connectable (0.04-80 ltr/min)

Accuracy:

0.5% of measured flow

Pressure measurement system:

1 pcs pressure transducers in each port (0-400 bar/ 0-5801 psi)

Accuracy:

0.25% of full scale

Filtration:

High pressure filters 3 micron abs Return filter 10 micron abs

Cooling system:

Water

Temperature range:

25-85 °C adjustable over control system

Control system:

– Hycom “Advantouch” control system with manual

– semi automatic and full automatic mode

PLC system:

Siemens S7

Data acquisition system:

National Instruments

Software environment:

Windows XP Professional / Labview

Servo current drivers:

± 10, ± 30, ± 60 mA (2 pcs)

LVDT demodulations:

4 pcs adjustable over control software

Adjustable power supplies:

1 pc 0-32 VDC 0-5 Amp

Test bench version

HNRCTS-L

Fluid type

L = mineral oil

C = phosphate ester

Flow range – main supply

50 = 50 ltr/min

100 = 100 ltr/min

190 = 190 ltr/min

240 = 240 ltr/min

Pressure range – main supply

210 = 210 bar / 3000 psi

350 = 350 bar / 5000 psi

Design no

38410

Various options can be added on customer’s request. It is also possible to supply the test stand with manual control system only.